Where Engineering Precision Meets Manufacturing Excellence

CircuitEDGE is a full service PCB and PCBA solutions provider delivering engineering driven design, fabrication, assembly, and electronics manufacturing services for high performance electronic systems. We work closely with product teams, OEMs, and system integrators to transform complex concepts into reliable, production ready hardware. By combining deep technical expertise, controlled manufacturing processes, and a global supply network, CircuitEDGE supports the complete product lifecycle from early design and prototyping to scalable production.

Circuit-Edge Services

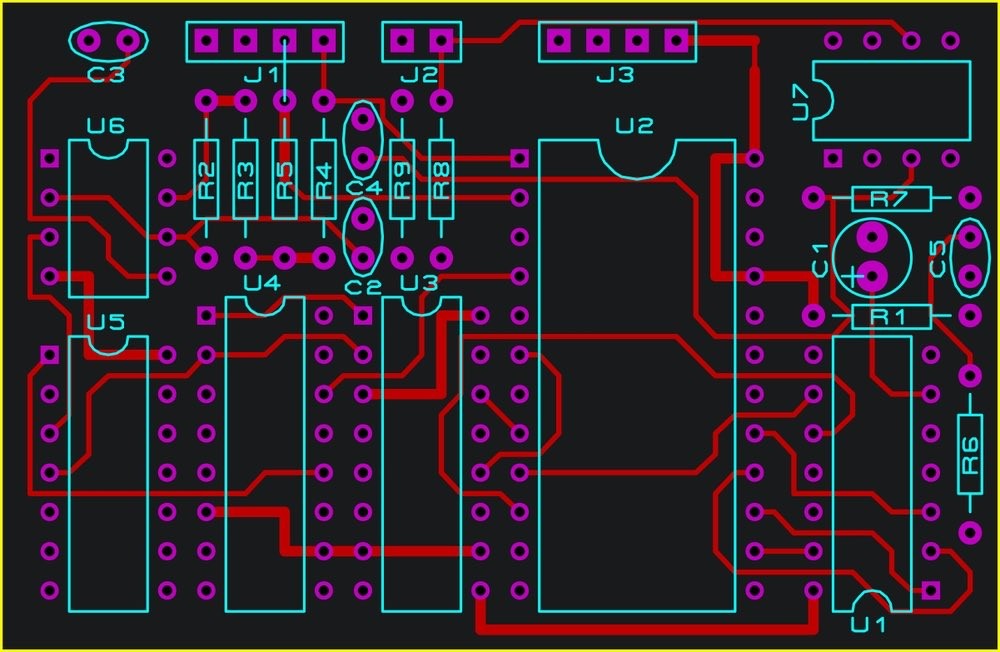

PCB Design

- Schematic Diagram

- PCB Layout Design

- Signal & Power Integrity

- Thermal Analysis

- Design for Testing/ Manufacturability/Assembly

PCB Fabrication

- Schematic Diagram

- PCB Layout Design

- Signal & Power Integrity

- Thermal Analysis

- Design for Testing/ Manufacturability/Assembly

Components Sourcing

- Schematic Diagram

- PCB Layout Design

- Signal & Power Integrity

- Thermal Analysis

- Design for Testing/ Manufacturability/Assembly

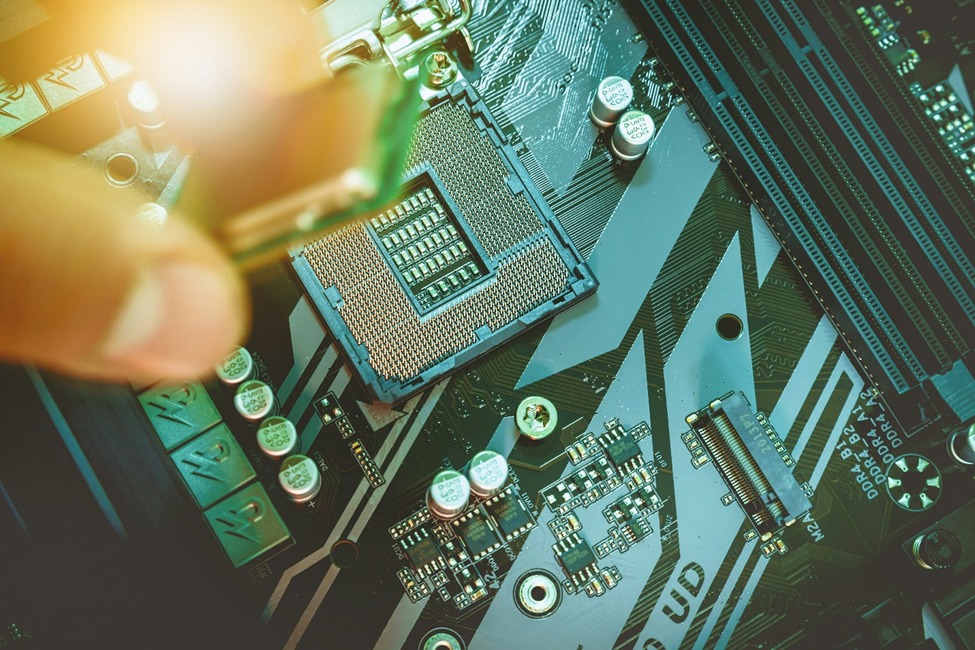

PCB Assembly

- Schematic Diagram

- PCB Layout Design

- Signal & Power Integrity

- Thermal Analysis

- Design for Testing/ Manufacturability/Assembly

Electronic Manufacturing

- Schematic Diagram

- PCB Layout Design

- Signal & Power Integrity

- Thermal Analysis

- Design for Testing/ Manufacturability/Assembly

Our Process

DFM Analysis

We perform detailed manufacturability reviews of customer design data, identifying improvement opportunities that enhance reliability, yield, and production efficiency for aerospace-grade PCBs.

PCB Manufacturing

Customer design data is evaluated through a structured manufacturing feasibility review, with targeted recommendations applied to improve PCB reliability, process stability, and overall production efficiency for aerospace applications.

Global Components Sourcing

Our sourcing team secures authentic components while managing shortages and price fluctuations through approved cross-references and equivalent part selection.

Precision PCB assembly

Our assembly processes employ RoHS-compliant, lead-free solder systems to meet environmental regulations without compromising reliability or performance.

Comprehensive Testing and Aging

High-voltage insulation testing and high-current load testing are conducted to verify performance under operating conditions representative of aerospace environments.

Traceability Assurance

We implement end-to-end barcode traceability, assigning each PCB a unique identifier to enable precise quality tracking and efficient post-delivery support.

What is CircuitEDGE?

CircuitEDGE is an engineering-led PCB and PCBA solutions provider supporting the complete electronics lifecycle from design and prototyping to fabrication, assembly, and scalable production.

We work with customers across industries to deliver reliable, high-performance circuit boards, whether for simple designs or complex, high-density systems.

Our team combines hands-on engineering expertise with controlled manufacturing processes to support projects of any scale, from low-volume prototypes to full production runs. By focusing on manufacturability, quality, and consistency, CircuitEDGE helps customers bring electronic products to market with confidence.

Our Commitment to Quality

Quality is embedded at every stage of the CircuitEDGE process. Our quality assurance framework combines advanced testing methodologies with disciplined process control to verify electrical performance, assembly integrity, and manufacturability.

We utilize a comprehensive range of inspection and test techniques, including Flying Probe, Fixture Testing, Impedance Testing, Automated Optical Inspection (AOI), X-ray inspection, ICT, FCT, open/short testing, and leakage analysis. Supported by modern equipment and experienced engineering teams, these processes ensure every PCB and PCBA meets defined performance, reliability, and compliance requirements before delivery.

Our Happy Customers

When we needed to advance our design to a high-speed 8-layer PCB, CircuitEdge reviewed my fabrication notes in detail and provided valuable feedback. The final boards were manufactured to an excellent standard and met all performance expectations.

The Bandwidth Calculator goes beyond basic calculations by enabling critical length analysis for multiple trace types. It also supports direct input of parameters such as DTR, frequency, and rise time, improving accuracy and overall usability.

We are extremely satisfied with the quality of work and the support provided. Their strong commitment to quality control and continuous improvement makes them a reliable partner for high-quality electronic manufacturing.

We are very satisfied with the overall experience. The team guided us smoothly through the production process, and their strong understanding of advanced technologies helped optimize our designs for high performance and cost efficiency.

"Absolutely fantastic service! My phone's screen was cracked, and GadgetFix had it fixed in no time. The repair was flawless, and the customer service was top-notch. Highly recommend!"

Our Partners

- Discover how our expertise can help with your next PCB project.

Stay updated with us

How PCB Design Decisions Impact Signal Integrity and System Reliability

As electronic systems continue to push higher data rates, tighter tolerances, and greater functional density, PCB design has become...

From Prototype to Production: Avoiding Common PCB Fabrication Pitfalls

Many electronic products fail to transition smoothly from prototype to production not because the design is flawed, but because...

PCB Assembly Best Practices for Fine-Pitch and High-Density Designs

As electronic products continue to shrink while performance requirements increase, fine-pitch and high-density PCB assemblies have become the norm...

Choosing the Right PCB Materials for High-Speed and High-Power Applications

PCB material selection plays a critical role in determining the electrical performance, thermal behavior, reliability, and manufacturability of modern...