IPC-6012 / IPC-A-600 fabrication standards for multilayer, HDI, and controlled-impedance structures

Advanced PCB Solutions for

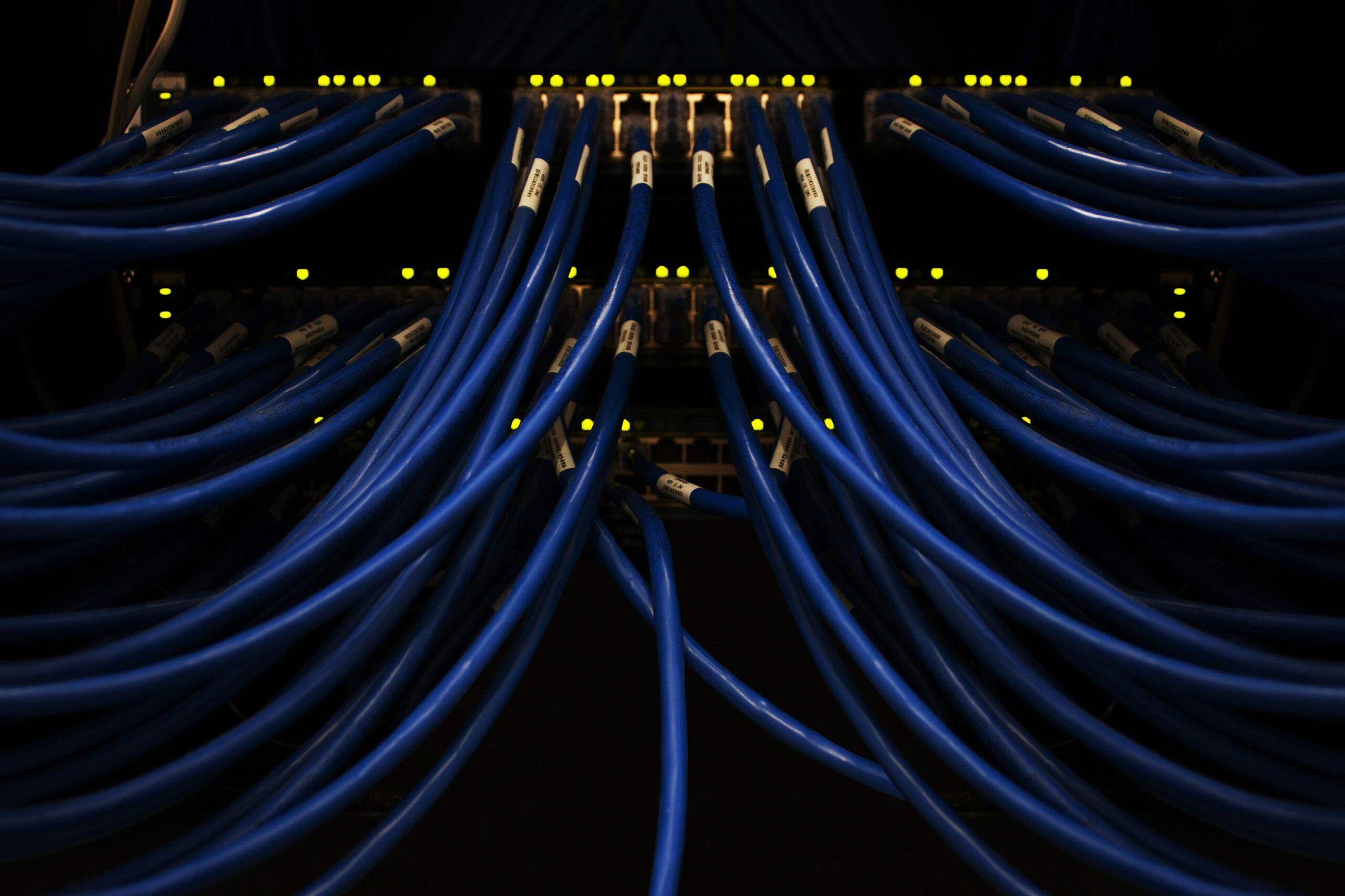

Telecommunications and Network Infrastructure

The telecom industry continues to evolve toward higher bandwidth, faster switching, and more reliable global connectivity. CircuitEDGE delivers PCB solutions engineered specifically for high-frequency, high-data-rate network systems. Our boards support the demanding performance requirements of base stations, routers, optical modules, 5G platforms, and other communication hardware. Each design is optimized for signal integrity, low latency, stable impedance, and the electrical performance needed to keep modern networks operating seamlessly.

Telecommunication & Networking PCB Design & Manufacturing in Dubai, United Arab Emirates

CircuitEDGE provides advanced PCB design and manufacturing services for telecommunication and networking equipment across Dubai, United Arab Emirates. Our engineering expertise covers RF front-end modules, high-speed digital interfaces, microwave circuits, optical communication boards, network switches, and 5G/6G infrastructure. We work with low-loss materials, controlled-impedance stackups, HDI architectures, and microvia technology to ensure stable signal transmission at multi-gigabit data rates. Every PCB undergoes rigorous DFM/DFA checks, impedance verification, AOI, X-ray inspection, and electrical testing to guarantee predictable performance in bandwidth-intensive, mission-critical network environments.

Key Requirements for Telecommunication & Networking PCB Design

Telecom electronics operate under demanding electrical and environmental conditions. PCB designs must address:

1: Stable signal integrity at high frequencies and high data rates

2: Controlled impedance for RF, microwave, and high-speed digital interfaces

3: Low insertion loss and minimal phase distortion

4: Strong EMI/EMC immunity in dense signal environments

5: Thermal stability for continuously operating equipment

6: Mechanical reliability for outdoor and remote installations

7: Long-term material and component availability

These requirements ensure consistent network performance, reduced downtime, and long service life.

Compliance and Quality Standards for Telecommunication & Networking PCBs

Telecommunication and networking hardware require PCBs that deliver predictable performance at high frequencies, high data rates, and continuous operating cycles. CircuitEDGE follows a strict compliance and quality framework to ensure every board meets the electrical, mechanical, and reliability demands of modern communication systems.

IPC-A-610 Class 2 or Class 3 assembly quality for fine-pitch, high-density digital and RF components

EMI/EMC compliance guidelines essential for routers, base stations, optical modules, and 5G/6G transceivers

RoHS & REACH environmental requirements for global telecom equipment deployment

AOI, X-ray, and electrical test coverage for validating signal-critical packages such as BGAs, QFNs, SiPs, and RF modules

Thermal and mechanical stability standards for equipment operating in outdoor, high-temperature, and high-humidity conditions

Applications & Use cased for Telecom Circuits and Network PCBs

CircuitEDGE supports a wide spectrum of telecommunications and networking sectors with engineered PCB solutions designed for high-frequency performance and long-term reliability. Key requirements include:

Radio Access & Wireless Infrastructure

PCBs for base stations, remote radio units, small cells, and wireless access systems supporting high-frequency and high-bandwidth communication.

Optical & Fiber Communication Systems

Boards for optical transceivers, high-density line cards, wavelength management modules, and coherent optical networking hardware. HDI architecture with microvias for dense FPGA and ASIC footprints

High-Speed Networking & Data Transport

PCBs for enterprise routers, carrier-grade switches, data-center interconnect devices, and multi-gigabit backbone equipment.

Customer Premises & Edge Devices

Electronics for gateways, modems, access points, and edge networking hardware enabling reliable last-mile connectivity.

Cloud & Data Center Networking

High-performance PCBs for switches, servers, and network acceleration hardware supporting scalable cloud infrastructure.

Network Security & Traffic Management Systems

PCBs for firewalls, intrusion detection systems, load balancers, and traffic optimization platforms that require high-throughput processing, low latency, and reliable operation under continuous network load.

Assembly & Testing for Telecom Electronics

Telecommunication systems require precise and repeatable assembly processes. CircuitEDGE provides:

1. Advanced SMT and mixed-technology assembly

2. Fine-pitch and BGA component handling

3. X-ray inspection for hidden solder joints

4. AOI for placement and solder verification

5. Electrical and functional testing

6. Full traceability and documentation

These processes ensure consistent quality and long-term operational stability.

Frequently asked questions

Yes. We specialize in high-speed digital and RF PCB designs with controlled impedance and low-loss materials.

Can you handle HDI and multilayer telecom PCBs?

Yes. CircuitEDGE offers end-to-end PCB design, fabrication, assembly, and component sourcing.

Yes. We support rapid prototyping, pilot runs, and scalable production.

Do you serve customers outside the UAE?