IPC-6012 / IPC-A-600 for PCB fabrication

Automotive PCB Manufacturing and Assembly

Automotive electronics require PCBs that deliver long-term reliability, functional safety, and consistent performance under harsh operating conditions. CircuitEDGE provides high-reliability PCB design, fabrication, and assembly solutions engineered for modern automotive platforms. Our boards are built to withstand temperature extremes, vibration, moisture, electrical noise, and extended service lifecycles demanded by today’s vehicles.

Automotive PCB Design & Manufacturing in Dubai, United Arab Emirates

CircuitEDGE supports automotive OEMs, Tier-1 and Tier-2 suppliers, EV manufacturers, and mobility technology providers across Dubai, United Arab Emirates, and global markets. We manufacture PCBs for powertrain electronics, body control modules, infotainment systems, ADAS platforms, battery management systems, and in-vehicle networking hardware.

Our engineering approach includes controlled-impedance routing, mixed-signal isolation, thermal optimization, and robust power distribution design. We work with automotive-grade laminates, high-temperature materials, heavy-copper constructions, and EMI-optimized layouts. Every design undergoes detailed DFM/DFA review, followed by AOI, X-ray inspection (where required), and electrical validation to ensure production readiness.

Key Requirements for Automotive PCB Design

Automotive applications impose strict mechanical, thermal, and electrical constraints. Critical PCB requirements include:

1. Operation across wide temperature ranges (−40°C to +125°C or higher)

2. Resistance to vibration, shock, and mechanical stress

3. EMI/EMC robustness for dense in-vehicle electronics

4. Stable power distribution for high-current and safety-critical systems

5. Long lifecycle support and component availability

6. Compliance with functional safety and quality standards

7. Compatibility with conformal coating and environmental protection

These requirements ensure consistent vehicle performance, safety, and durability throughout the vehicle lifecycle.

Standards Apply to Automotive PCBs

Incorporating the appropriate intent requires understanding the standards that apply to the development of your boards.

IPC-A-610 Class 2 or Class 3 assembly standards

Automotive-grade material and process control

EMI/EMC compliance aligned with automotive regulations

RoHS & REACH environmental compliance

AOI, X-ray, and electrical testing for complex assemblies

Full traceability and documentation for production programs

AS9102B specifies FAI requirements. This crucial verification ensures initial units meet all design and specification requirements before full production.

Automotive Applications

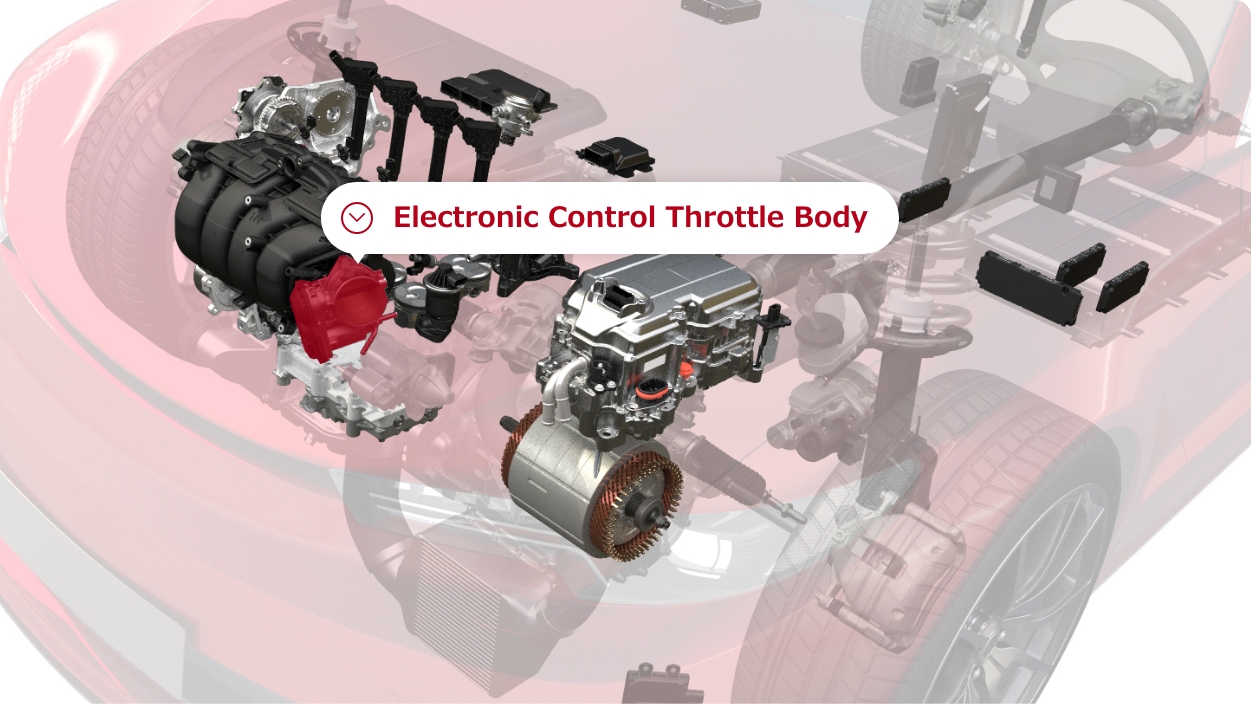

Powertrain & Engine Control Systems

PCBs for engine control units (ECUs), transmission control, fuel management, and emission systems requiring stable operation under high thermal and electrical stress.

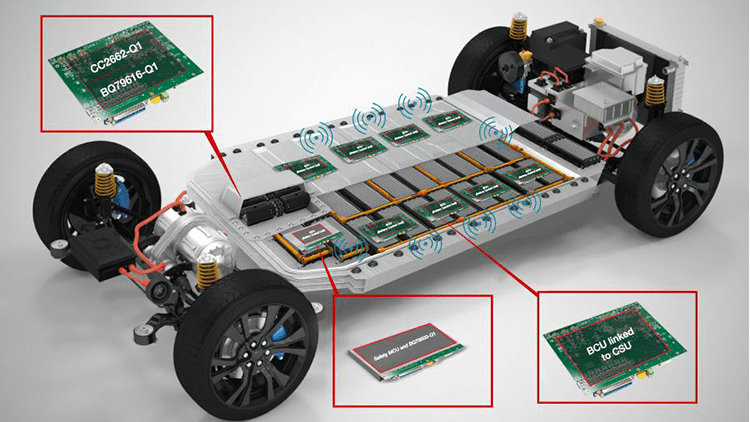

Electric Vehicle (EV) & Hybrid Systems

Boards for battery management systems (BMS), onboard chargers, DC/DC converters, inverters, and power distribution units optimized for high current and thermal efficiency.

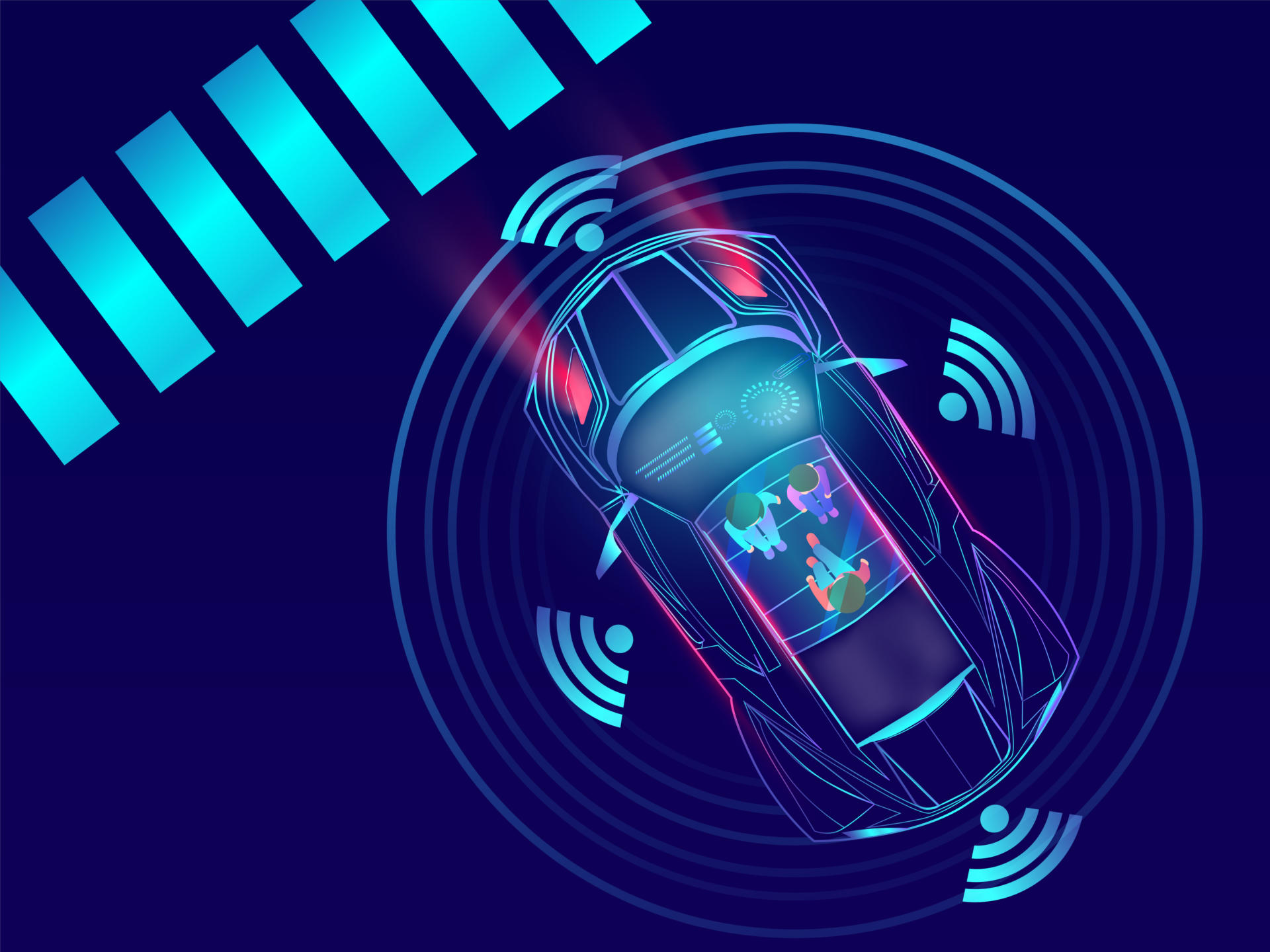

ADAS & Safety Systems

High-reliability PCBs for radar modules, camera systems, LiDAR interfaces, braking control units, and driver-assistance platforms.

Infotainment & Connectivity

PCBs for infotainment head units, navigation systems, in-vehicle networking (CAN, LIN, FlexRay, Automotive Ethernet), and telematics modules.

Body Control & Comfort Electronics

Electronics for lighting control, climate systems, access control, seat management, and vehicle interior automation.

Sensors & Monitoring Systems

PCBs supporting pressure, temperature, motion, proximity, and environmental sensing throughout the vehicle.

Assembly and Testing Processes

Automotive electronics require controlled and repeatable manufacturing processes.CircuitEDGE provides:

• Precision SMT and mixed-technology assembly

• X-ray inspection for BGAs, QFNs, and fine-pitch components

• AOI for solder joint and placement integrity

• Electrical testing for continuity and isolation

• Functional testing based on system requirements

• Preparation for conformal coating and environmental protection

• Full production traceability and documentation

These processes ensure each PCB meets automotive reliability and safety expectations.

Frequently asked questions

Yes. We manufacture PCBs using automotive-grade materials and processes aligned with industry reliability requirements.

Yes. We specialize in heavy-copper and thermally optimized PCBs for EV and hybrid power systems.

Yes. We plan materials, components, and documentation to support extended vehicle production lifecycles.

Yes. We support rapid prototypes, engineering builds, and scalable production.

Yes. CircuitEDGE supports automotive programs across the GCC and global markets.