IPC-6012 / IPC-A-610 Class 2 or 3 fabrication and assembly

Energy & Power Electronics

PCB Manufacturing and Assembly

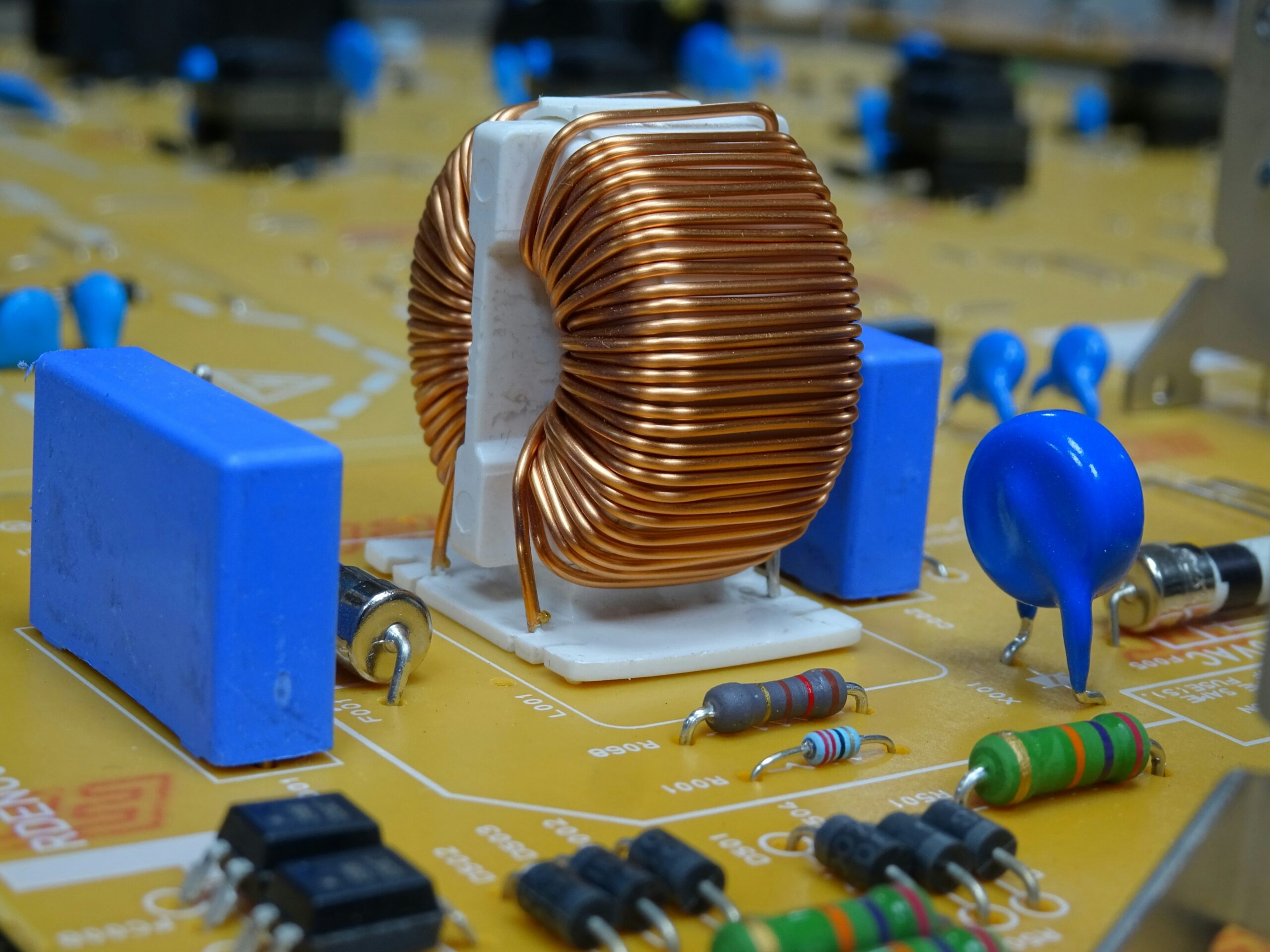

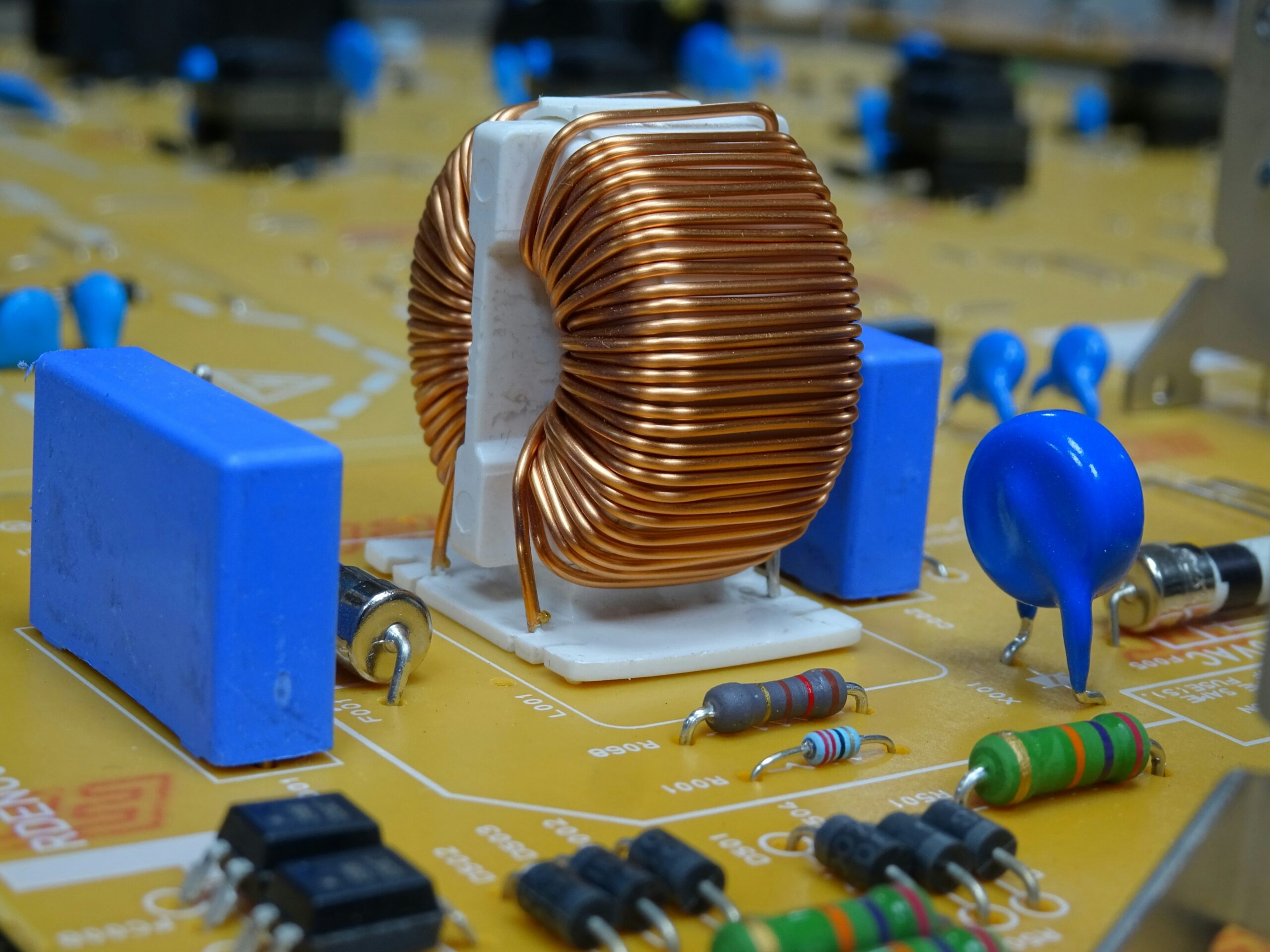

Power electronics play a critical role in modern energy systems, requiring PCBs that can withstand high voltages, elevated current loads, thermal stress, and continuous operation. CircuitEDGE delivers engineered PCB solutions specifically tailored for renewable energy platforms, power conversion systems, grid infrastructure, EV charging, battery management units, and industrial power modules. Our focus is on stability, efficiency, and long-term durability—key requirements for power systems deployed in demanding environments.

Energy & Power Electronics PCB Manufacturing

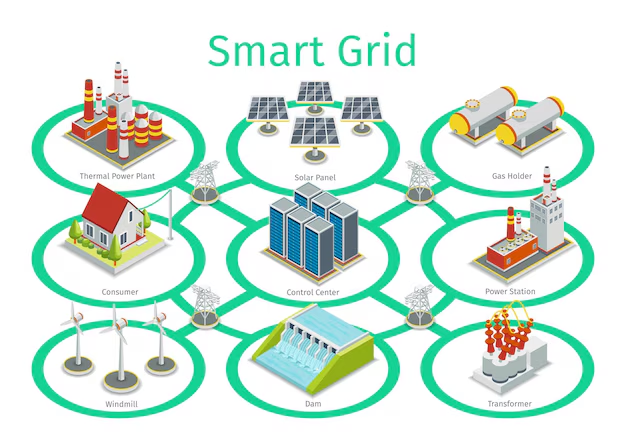

CircuitEDGE supports the region’s growing energy sector with advanced PCB manufacturing and assembly services Across globally. Our designs are optimized for robust electrical isolation, efficient heat dissipation, and reliable conduction paths necessary for converters, inverters, rectifiers, high-current switching modules, and smart-grid electronics.

We work with thick-copper PCBs, metal-core substrates, ceramic boards, and reinforced dielectric materials to ensure strong performance in thermal cycling, surge conditions, and sustained peak load operation. Our engineering team provides guidance on creepage/clearance, thermal spreading, and EMI suppression to ensure compliance with global energy and safety regulations.

Key Requirements for Power Electronics PCB Design

Power electronics demand a design approach centered on electrical safety, thermal efficiency, and high-current reliability. Essential requirements include:

1: Thick copper (2 oz – 6 oz+) for high-current paths

2: Optimized thermal vias and heat-spreading architectures

3: High-temperature substrates for sustained load operation

4: Robust isolation for high-voltage sections

5: Reinforced creepage and clearance geometry

6: EMI/EMC control for switching systems

7: Long-term component availability for lifecycle stability

These considerations ensure efficient power conversion, minimal loss, and dependable operation under continuous duty cycles.

Compliance and Safety Standards

Energy-focused PCBs must align with strict global electrical and environmental standards.

UL standards for electrical insulation and thermal exposure.

RoHS/REACH environmental compliance

EMI/EMC regulations for power conversion hardware.

IEC/EN safety requirements for high-voltage equipment.

AS9102B specifies FAI requirements. This crucial verification ensures initial units meet all design and specification requirements before full production.

Core Applications of Energy & Power Electronics PCBs

Solar Inverters & Renewable Energy Converters

We manufacture PCBs for MPPT stages, DC/DC converters, and inverter power modules. Boards are optimized for thermal dissipation, high-voltage isolation, and efficient switching performance.

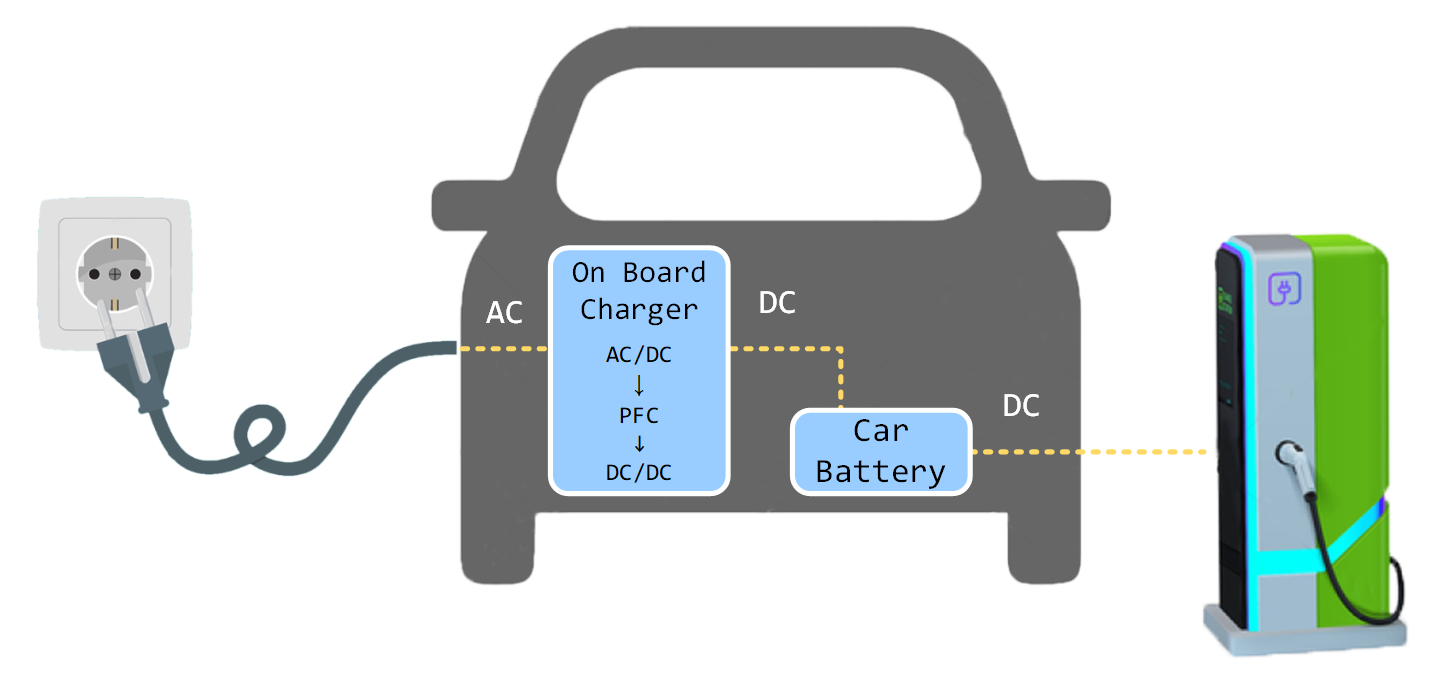

EV Charging & Onboard Power Systems

CircuitEDGE provides heavy-copper and insulated substrates for AC/DC conversion, power factor correction (PFC), and fast-charging modules used in electric vehicle infrastructure.

Battery Management Systems (BMS)

Our BMS boards support cell monitoring, balancing circuits, safety protection, temperature tracking, and communication with vehicle or grid systems.

Industrial Power Supplies & UPS Systems

We build PCBs for rectifiers, SMPS units, backup power modules, and industrial-grade AC/DC conversion blocks, ensuring predictable behavior under fluctuating loads.

Smart Grid & Energy Monitoring Devices

CircuitEDGE manufactures control and communication boards for grid sensors, metering units, load controllers, and distribution automation modules.

High-Power Motor Drives & Conversion Units

CircuitEDGE manufactures PCBs for industrial power supplies, converters, and battery-backup systems using optimized thermal management and high-voltage isolation strategies.

Assembly & Testing for Power Electronics

Power boards require precise, controlled assembly processes:

1: Heavy-copper reflow optimization

2: Selective soldering for high-current connectors

3: X-ray inspection for dense power packages

4:Thermal validation and stress testing

5: Isolation testing to meet voltage requirements

6: Functional testing for switching performance and efficiency

This ensures stability and safety in high-energy environments. Functional testing for communication buses, power paths, and sensor interfaces

Frequently asked questions

CircuitEDGE supports PCBs for power converters, inverters, DC/DC converters, battery management systems (BMS), power distribution units, renewable energy systems, and industrial power control electronics.

Yes. We design and manufacture PCBs with heavy copper, reinforced power planes, wide trace geometries, and controlled spacing to safely support high-current and high-voltage operation.

Thermal performance is addressed through copper thickness optimization, thermal vias, heat-spreading structures, material selection, and layout strategies that reduce hotspots and improve heat dissipation.

Yes. We support PCBs for solar inverters, energy storage systems, EV charging infrastructure, and grid-connected power electronics where efficiency and long-term reliability are critical.

Depending on system requirements, we use standard and high-Tg FR-4, heavy copper constructions, metal-core PCBs, and thermally optimized laminates to meet electrical and thermal demands.

Yes. CircuitEDGE supports energy and power electronics customers across Dubai, the UAE, GCC, and global markets.