IPC-6012 / IPC-A-610 Class 2 or Class 3

Semiconductor PCB Manufacturing and Assembly for

Advanced Electronic Systems

Semiconductor technologies demand an exceptionally precise and stable electronic foundation. CircuitEDGE supports this sector with high-performance PCB manufacturing and assembly solutions engineered for chip evaluation boards, test platforms, semiconductor equipment, packaging systems, power modules, high-speed interfaces, and advanced mixed-signal designs. Our manufacturing processes emphasize signal integrity, controlled impedance, thermal reliability, and repeatable performance—critical factors for semiconductor R&D and production environments.

Semiconductor PCB Design & Manufacturing in Dubai, United Arab Emirates

CircuitEDGE provides advanced PCB engineering and production services to semiconductor companies, R&D labs, automated test equipment (ATE) developers, and device manufacturers across Dubai, United Arab Emirates. We specialize in PCBs used for chip development boards, probe test systems, FPGA evaluation modules, high-frequency transceivers, power semiconductor drivers, and supporting electronics used in wafer fabrication equipment.

Our designs leverage low-loss materials, high-speed laminates, HDI structures, and controlled dielectric stackups suitable for multi-GHz digital, RF, and mixed-signal circuits. We work closely with engineering teams to ensure stable timing, clean analog paths, low jitter, and reliable interconnects essential for semiconductor validation and production workflows. Each board undergoes DFM/DFA analysis, impedance verification, AOI, X-ray inspection, and electrical testing to guarantee accuracy and repeatability.

Key Requirements for Semiconductor PCB Design

Semiconductor hardware places extreme demands on PCB performance—especially in high-speed and precision measurement environments. Key requirements include:

1: Ultra-low-loss substrates for high-speed digital and RF domains

2: Controlled impedance for multi-GHz differential interfaces

3: HDI architecture with microvias for dense FPGA and ASIC footprints

4: Minimal skew, crosstalk, and signal distortion

5: Stable dielectric behavior across wide temperature ranges

6: High-accuracy routing for chip evaluation and test boards

7: Thermal design to support power semiconductors, drivers, and regulators

8: Clean analog pathways for precision sensing and measurement

These requirements ensure predictable and repeatable performance in semiconductor development and production systems.

Compliance and Quality Standards for Semiconductor PCBs

CircuitEDGE adheres to strict manufacturing and quality standards essential for semiconductor applications:

Controlled impedance verification and coupon testing

RoHS & REACH compliance

Electrical, AOI, and X-ray inspection for every batch

Traceability documentation for materials and components

Sets the QMS requirements for aerospace suppliers. Covers processes (in-house/outsourced), management, emphasizing customer satisfaction.

Specifies guidelines for the auditing and reporting of your QMS, ensuring its ongoing effectiveness and compliance with stringent aerospace requirements.

AS9102B specifies FAI requirements. This crucial verification ensures initial units meet all design and specification requirements before full production.

Core Applications of Semiconductor PCBs

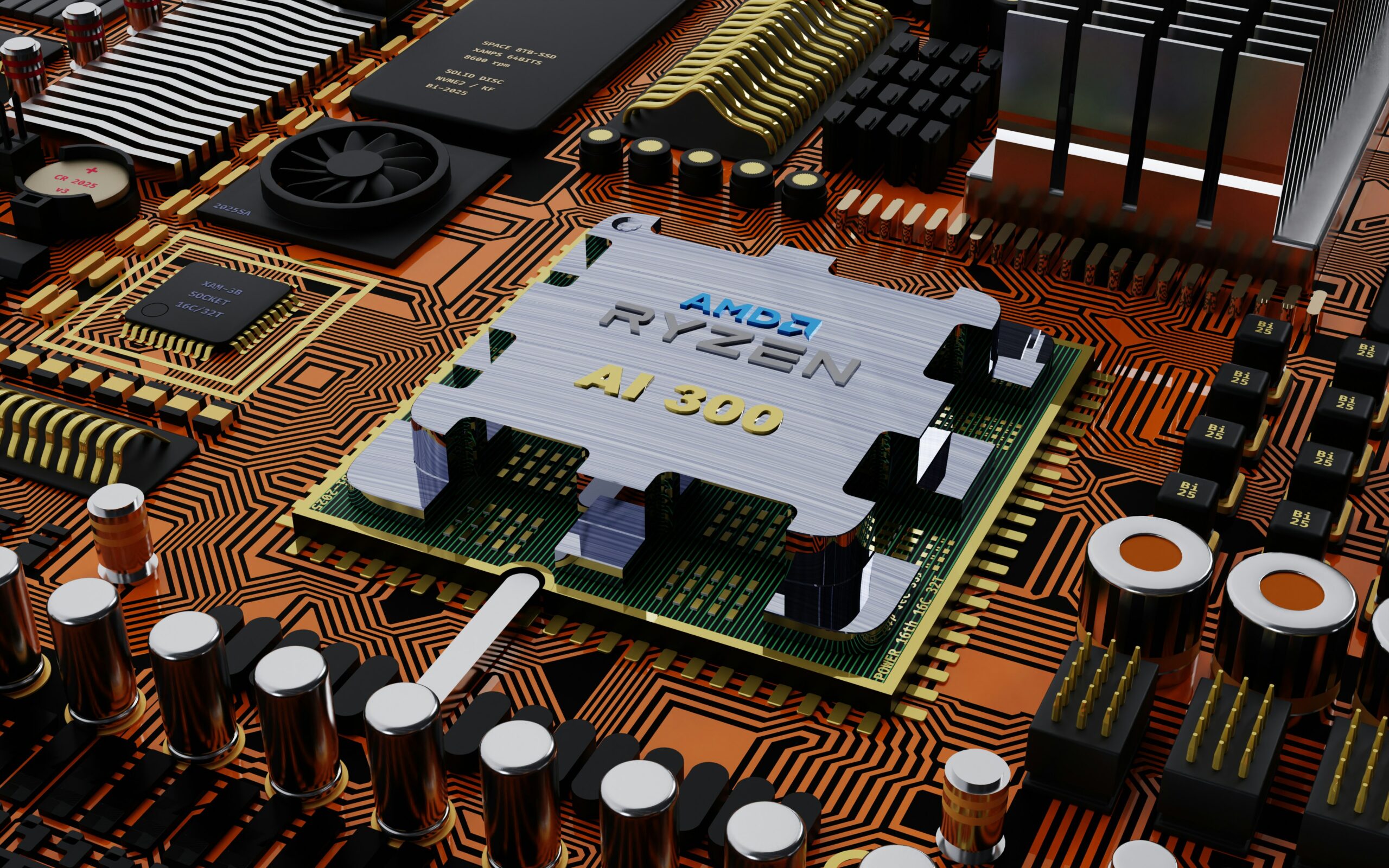

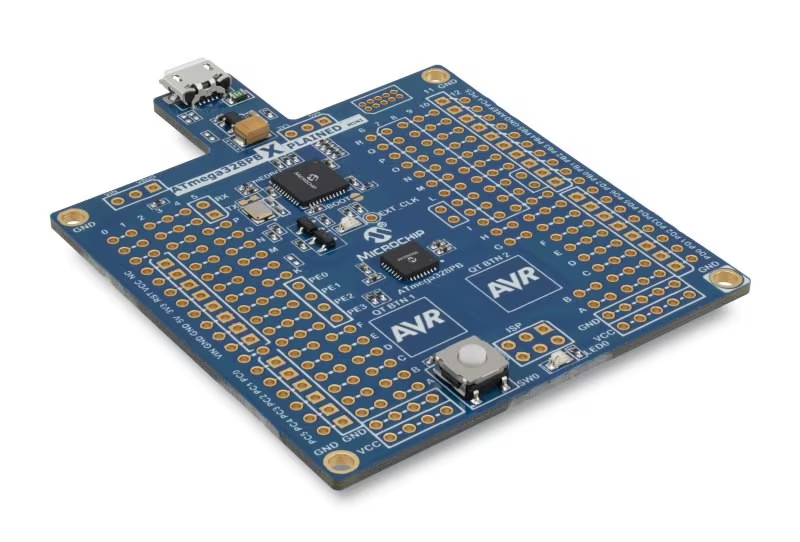

Chip Evaluation & Development Boards

CircuitEDGE manufactures PCBs for ASIC, FPGA, microcontroller, RFIC, and mixed-signal chip evaluation platforms. These boards prioritize stable impedance, clean signal paths, and precise interconnects for accurate device characterization

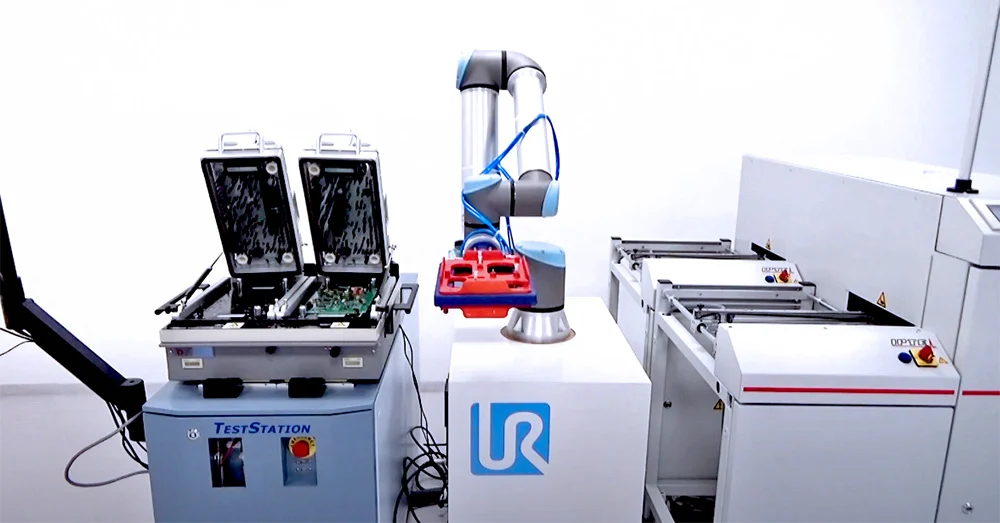

Automated Test Equipment (ATE) & Test Fixtures

We build high-density PCBs used in semiconductor testing environments, including probe card interfaces, load boards, interface boards, and instrumentation PCBs. Tight tolerances and low-loss materials ensure reliable measurement accuracy.

Power Semiconductor Drivers & Control Units

Our boards support Si, SiC, and GaN semiconductor drivers used in power modules, converters, motor control, and high-efficiency switching systems. Designs feature reinforced isolation, thermal optimization, and robust creepage/clearance.

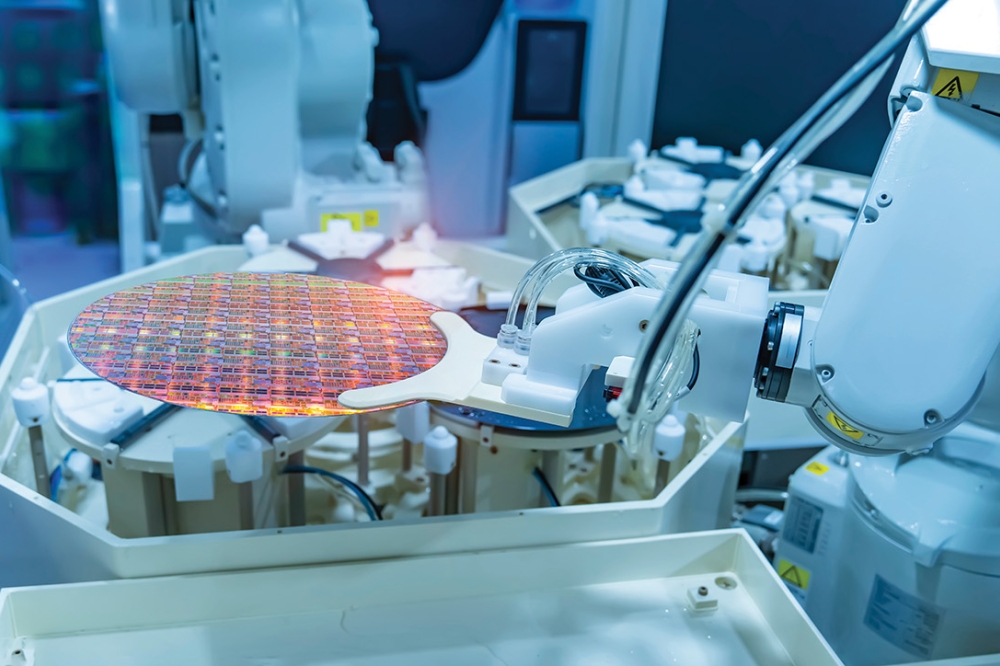

Semiconductor Manufacturing Equipment Electronics

CircuitEDGE produces PCBs for wafer handling systems, lithography modules, deposition equipment, plasma tools, and automated inspection devices. Reliability, temperature stability, and EMI robustness are priorities for these systems.

High-Speed Digital Platforms

We manufacture high-density boards for multi-gigabit SerDes, DDR interfaces, PCIe modules, high-bandwidth memory controllers, and other semiconductor-related digital platforms.

RF & Microwave Semiconductor Systems

Boards for RFIC characterization, mmWave verification, low-noise amplifiers, phased-array modules, and transceiver development use advanced laminates and RF-optimized routing strategies.

Semiconductor PCB Assembly & Testing

Assembly for semiconductor applications requires extreme precision, repeatability, and documentation. CircuitEDGE performs:

1: Fine-pitch SMT assembly for advanced BGAs, LGAs, CSPs, and ultra-dense ICs

2: X-ray inspection for all hidden-joint packages

3: Controlled reflow profiles for multi-layer HDI and low-loss materials

4: Functional testing for high-speed digital and RF circuits

5: Boundary scan, JTAG programming, and device bring-up

6: Full traceability for engineering records

This ensures every board used in semiconductor workflows meets the expected electrical and mechanical performance criteria.

Frequently asked questions

Chip evaluation boards, RFIC/ASIC/FPGA test boards, ATE load boards, power semiconductor drivers, and electronics for wafer equipment.

Yes. We specialize in microvia, blind/buried via, and high-density architectures required for advanced IC packaging.

Absolutely. We manufacture PCBs with controlled impedance, low-loss laminates, and precision routing for multi-GHz interfaces.

Yes—rapid prototypes, engineering samples, and scalable mass-production.

Yes. We work with Rogers, Taconic, and other RF-grade substrates for high-frequency semiconductor applications.