IPC-6012/IPC-A-600 for the fabrication of high-reliability PCBs.

Railway Electronics: PCB Manufacturing and Assembly

Modern railway systems depend on electronics that are exceptionally robust, precise and reliable, whether they are used in rolling stock, wayside infrastructure, signalling systems or onboard communication platforms. CircuitEDGE provides high-performance PCB design, fabrication and assembly solutions that are specifically engineered for the harsh environmental, electrical and safety requirements of railway technology. Our boards are designed to withstand vibration, temperature extremes, electromagnetic interference and the long service lifecycles typical of rail environments.

PCB design and manufacturing for the railway industry

CircuitEDGE provides comprehensive PCB engineering and manufacturing support for railway operators, signaling OEMs, transportation technology integrators and industrial automation providers across global markets.

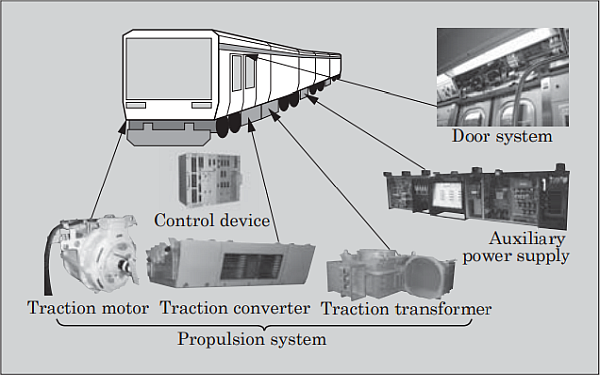

We have expertise in traction control electronics, braking systems, telemetry units, railway communication (TCN/ETCS), passenger information systems, surveillance modules and infrastructure monitoring devices. We use high-reliability laminates, heavy-copper constructions, reinforced dielectric materials and EMC-optimized layouts to ensure reliable operation over thousands of hours.

Key requirements for railway electronics PCB design

Railway systems impose unique electrical, mechanical and environmental requirements on PCB design. Critical considerations include:

1. High vibration and shock resistance for rolling stock applications

2. Wide operating temperature ranges (typically −40°C to +85°C or higher).

3. EMC immunity for noisy electrical environments (e.g. traction motors and high-current switching).

4. Reinforced creepage/clearance for high-voltage subsystems

5.Long lifecycle component planning for systems deployed for 10–20 years.

6. Heavy copper options are available for power, braking and traction electronics.

7. Conformal coating compatibility to resist dust, humidity and pollution.

These requirements ensure stable, long-term performance in dynamic railway environments.

Compliance & Quality Standard

CircuitEDGE adheres to global standards and manufacturing guidelines for railway electronics, including:

IPC-A-610 Class 2 or Class 3 assembly requirements.

EN 50155 is supported where customer workflow requires it for onboard railway electronics.

EMI/EMC compliance is aligned with EN 50121-3-2.

UL and RoHS/REACH environmental and safety requirements.

Sets the QMS requirements for aerospace suppliers. Covers processes (in-house/outsourced), management, emphasizing customer satisfaction.

Electrical and functional testing for electronics intended for long-term service.

AS9102B specifies FAI requirements. This crucial verification ensures initial units meet all design and specification requirements before full production.

Core applications of railway electronics PCBs

Railway Signaling & Control Systems

PCBs are engineered for use in interlocking, ETCS/ERTMS, ATP and wayside control units, and are designed to be fault tolerant, immune to noise and capable of stable long-term operation.

Traction, braking and power electronics

Boards for traction inverters, braking controllers, power distribution modules and auxiliary converter systems, featuring heavy copper and reinforced insulation.

Onboard communication and networking

PCBs that support TCN and Ethernet-based train networks, as well as wireless communication modules and passenger information systems, all of which have high EMC resilience.

Condition monitoring and predictive maintenance

Sensor and data acquisition boards for vibration monitoring, axle counting, temperature sensing and infrastructure diagnostics.

Passenger comfort and safety systems

Electronics for HVAC control, lighting modules, CCTV, emergency systems and access control units are designed for reliability and low maintenance.

Ticketing, control and automation hardware

PCBs for fare collection systems, access gates, contactless readers, control panels and station automation electronics.

PCBs Assembly and Testing

The manufacturing processes for railway electronics are designed for durability, thermal reliability and safety-critical performance.

CircuitEDGE performs:

1. Precision SMT and THT assembly

2. X-ray inspection of hidden-joint components (BGAs/QFNs).

3. AOI for solder quality and mechanical integrity

4. Electrical testing under load

5. Burn-in testing (on request).

6. Functional and communication interface testing.

7. Conformal coating for use in field environments.

These tests ensure that every board is ready for high-demand railway operation.

Frequently asked questions

Yes. We support design and documentation practices aligned with EN 50155 and partner with compliant manufacturing facilities.

Yes. We manufacture thick-copper boards (up to 6 oz+) suitable for high-current railway power applications.

Through design reinforcement, correct component selection, solder joint reliability processes, and mechanical support strategies.

Absolutely—our capabilities span onboard electronics, signaling, networking, power systems, and infrastructure devices.

Yes. Our boards are prepared for conformal coating and environmental sealing as required by railway deployments.