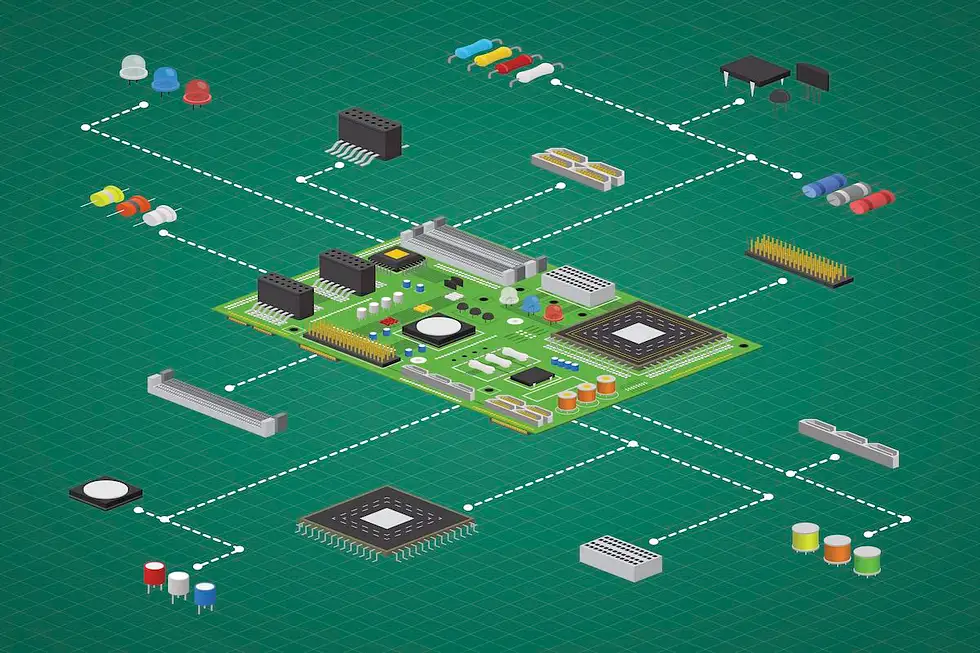

Turnkey EMS Manufacturing Solutions

CircuitEDGE provides end-to-end Turnkey Electronics Manufacturing Services (EMS), managing the complete process from design readiness and material procurement to PCB assembly, testing, and final delivery. Our turnkey model enables customers to focus on product innovation while we take responsibility for execution, quality, and supply chain coordination.

End-to-End Manufacturing Responsibility

Our turnkey EMS solution covers the entire manufacturing lifecycle, ensuring accountability at every stage:

1. Design for Manufacturability (DFM) & Design for Assembly (DFA) review

2. PCB fabrication

3. Component sourcing and procurement

4. PCB assembly (SMT, THT, mixed technology)

5. Inspection, testing, and quality assurance

6. Packaging and logistics coordination

This single-point responsibility minimizes risk, shortens lead times, and improves overall build consistency.

Component Sourcing & Supply Chain Management

Component availability and lifecycle risks are critical challenges in electronics manufacturing. CircuitEDGE manages sourcing through a qualified global supplier network, ensuring:

1. Genuine components with full traceability

2. BOM optimization for cost, availability, and longevity

3. Alternate part recommendations where required

4. Obsolescence and lead-time risk mitigation

We align component selection with both current build requirements and future production scalability.

PCB Assembly Capabilities

A. Assembly Technologies

1. SMT, THT, and mixed-technology assembly

2. Fine-pitch components, BGA, QFN, LGA

3. High-density and multilayer assemblies

4. Lead-free, RoHS-compliant processes

B. Production Volumes

1. Low-volume, high-mix builds

2. Pilot runs and NPI

3. Scalable to medium and high-volume production

C. Quality, Inspection & Testing

Quality is embedded into every stage of our turnkey EMS process and aligned with IPC standards.

1. AOI (Automated Optical Inspection)

2. Electrical testing (continuity and shorts)

3. Visual and mechanical inspection

4. Functional testing support (as per customer requirements)

5. Process documentation and traceability

D. New Product Introduction (NPI) Support

CircuitEDGE supports customers during NPI and early production phases, where manufacturing decisions directly impact yield, reliability, and cost.

Our NPI support includes:

1. Engineering review before build release

2. Manufacturing process optimization

3. Early issue detection and corrective actions

4. Feedback loop for design refinement

Industries We Support

1. RF and telecommunications

2. Aerospace & defense

3. Automotive electronics

4. Medical and instrumentation

5. Consumer and IoT devices

6. Semiconductors

7. Research & Development

8. Education

9. Industrial Automation & Controls

- Discover how our expertise can help with your next PCB project.